Turnkey Solutions for Nonalcoholic Beer & Wine.

Schmidt® SIGMATEC Dealcoholization System

Plate Heat Exchanger Heightens Product Quality at Dare Foods.

Schmidt® SIGMASTAR Evaporation Systems

Our Schmidt evaporization systems with SIGMASTAR® Climbing-film Plate Evaporators are used in the food industry, in the organic and chemical industry, and for wastewater treatment.

Advantages of the rising-film SIGMASTAR® include

- Superior product distribution due to the thermo-siphon principle

- Extremely short residence time, to guarantee a gentle treatment of the product

- Low pressure losses across the tubes, a benefit of the short tube length

- High concentrations and viscosities are possible due to the high vapor velocity in a rising film

- Clearly defined product flow path. There is no chance of local over-concentration

- Lower cost heat transfer area, compared to other evaporation systems

- No components are welded to the plate surface that can cause corrosion and build up of fibrous materials

- Flexible design – capacity changes can be made easily by adding or removing plates

The unique construction of the SIGMASTAR® evaporization plates makes it possible to apply SIGMASTAR® in a number of different evaporization processes. With problem products (e.g. viscous streams, slurries, and liquids with fouling tendencies) which cannot be processed with falling film evaporators, the SIGMASTAR® evaporizer performs especially smoothly and successfully.

Each of these pressed plates is approximately 0.9 m wide, 1.8 m high with longitudinal, sinus form corrugations, which extend over the full width of the plate. The flow passages on the plates are sealed by gaskets held in place by adhesive. This construction has several technical advantages.

Process Description

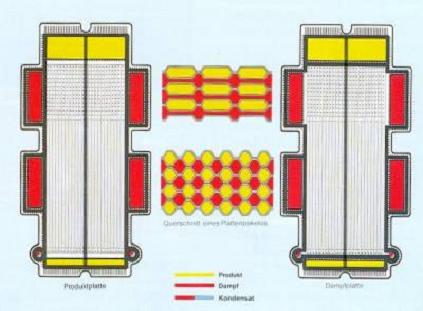

Our evaporation systems are constructed of steam and product plates, where steam condenses on one side of the plate while product boils on the other. Plates are aligned in the system so that vertical channels form in a circular shape. These channels can be conisdered “psuedo” tubes, resulting in a construction that combines the advantages of both plates and tubes.

Due to the special design of the upper part of the heat transfer surface, the heating steam is distributed evenly over the complete width of the plate. The cross-sectional flow area is the same on both sides of the plate, which ensures a well balanced feed into the heating channels.

Two Product Processing

Also available is our SIGMASTAR®-45V plate, a variation of the SIGMASTAR®-90V. This plate has an additional gasket down the center of the plate, which allows two products to be processed simultaneously. In this set up, steam can enter either the left, the right, or both sides of the plate, and the condensate exits from the bottom of the corresponding side of the plate. This can be seen in the figure below:

The SIGMASTAR®-90V and the SIGMASTAR®-45V can be combined in many different ways to increase the flexibility of our systems, especially for small duties. As the dimensions of both plates are identical, the same frame supports can be used. Expansions and modifications involving both plate types are possible at any time.

Schmidt® SIGMATHERM Pasteurization Systems

Our Schmidt SIGMATHERM Pasteurization System is the trusted choice for beverage and liquid food customers worldwide. At API Heat Transfer, we have extensive experience in pasteurization process technology and understand the importance of this operation in your facility. Our SIGMATHERM systems ensure food quality at low operating costs.

Advantages of SIGMATHERM Pasteurization Systems

- Low thermal load on the products

- Long life expectancy of the plant

- Low heating costs

- Compact construction

- Fully automated control available

- Heat recovery up to 96%

Process Descriptions:

Pasteurization

Our SIGMATHERM Pasteurization System is a high temperature short-time heating system (HTST) for the pasteurization of beverages and liquid foods such as juices, beer, milk, sauces, fruit and vegetable purees, tomato paste, jams and jellies, applesauce, liquid eggs, etc. These products are typically filled into refrigerated containers and have a limited shelf life of several days to several weeks.

A product passing through an HTST is preheated in the heat recovery section. It is then brought to pasteurization temperature in the heating section and held for a prescribed time in the holding tube before the temperature is lowered in the heat recovery section. It is finally cooled to a temperature for packaging and storage.

Process plants can be entirely based on the SIGMA plate heat exchanger which is capable of up to 96% heat recovery. SIGMAFLOW tubular heat exchangers and direct steam injection systems provide an alternative design for viscous, pasty, pulpy and particulate liquid foods.

Basic systems are supplied with hardware controllers and manually operated valves. Packages are also available with fully automated valves, instrumentation and control systems featuring touch screen and PLC control.

Aseptic processing

For extended shelf life (ESL) applications, higher temperature sterilization systems are offered for either high acid (pH < 4.5) or low acid (> 4.5) products. The design of these systems is similar to pasteurizers, but they usually feature more instrumentation and fully automatic control systems.

When combined with cold packing in refrigerated containers, these short-time thermal processing systems are known as ultra high temperature or UHT processors. When combined with packing into sterile containers at ambient temperature, the thermal processor must be an aseptic design.

For low acid ESL applications, regulatory authorities such as the FDA will be involved. Microbiological validation and review of control protocols are necessary to ensure the thermal processor and filler are working both safely and correctly.

Process plants with SIGMA plate heat exchangers or SIGMAFLOW heat exchangers for viscous, pasty, pulpy and particulate liquid foods have heat recovery capability up to 96%.

High temperature short time heating systems can be used for the cold packaging of food products in sterile containers via aseptic fillers into packages or barrels.

A product passing through a high temperature short time heating system is pre-heated in the heat recovery section, it is then brought to pasteurization temperature in the heating section, held for prescribed time in the holding tube before the temperature is lowered in the heat recovery section, and finally cooled to the packaging or storing temperature of around 20-25 °C (68-77 °F).

When a corresponding heat recovery system is installed for the cold processing of foodstuffs, then the cooling section can be dispensed with.

The plants can be fitted with basic controls, with for example hardware-controllers and manually operated valves or with fully automated controls with, for example software-controllers, SPC and computerised process controls.

Schmidt® SIGMATEC Dealcoholization Systems

Our Schmidt SIGMATEC Dealcoholization System has been designed for the dealcoholization of wine and beer. With experience in brewing that dates back more than 140 years, our SIGMATEC process represents another successful development in our line of Schmidt thermal systems. This new procedure uses continuous vacuum rectification to ensure a gentle removal of alcohol for a quality and enjoyable end product.

Advantages of SIGMATEC Dealcoholization Systems

- Selective alcohol separation with minimal aroma loss

- Gentle dealcoholization using low temperature vacuum technology

- Complete dealcoholization to less than 0.1 % alcohol

- Optimum adaptability to different products and formulations

- Operation with hot water or steam

- Performance data: 4-100 hl/h and more

- Completely continuous and automatically controlled

- No effluent problems

- Industrial alcohol as subsidiary end product, ready for immediate marketing

Process Description:

After degassing, the product is preheated in our SIGMA plate heat exchanger and is then fed to the stripping section of a rectifying column.

The fluid flows down the column at a temperature between 43 and 48°C. Through counter flow, the product contacts rising vapors which bring about the selective separation of the alcohol from the product.

The alcohol free wine/beer is then fed from the bottom of the column into an evaporator. In the evaporater, vapors are produced, which are necessary for the rectification process. These are then redirected into the column. The completely dealcoholized product is pumped out of the plant via a cooler.

The alcohol rich vapors pass from the stripping section to the rectification section where they are concentrated to 75% alcohol.

In the patented Aroma Recovery Unit, aroma components are recovered and redirected into the wine/beer. The alcohol rich vapors are condensed, cooled to a low temperature, and stored in a tank in the form of industrial alcohol. The result is a saleable product, which can be marketed immediately.