Water Cooled Charge Air Coolers

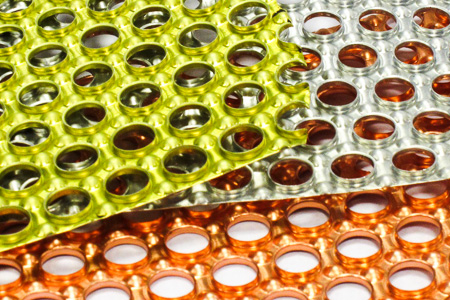

Custom designed in round shell and tube, or square engine and remote mounted fin designs, our high performance water cooled charge air coolers utilize extended surface cooling fins in either aluminium, copper, or stainless steel to ensure greater thermal effectiveness and durability. This means our customers receive superior performance at a practical price. For over 100 years, our heat exchangers have been trusted among equipment manufacturers in the transportation, power generation, construction, military and process industries.

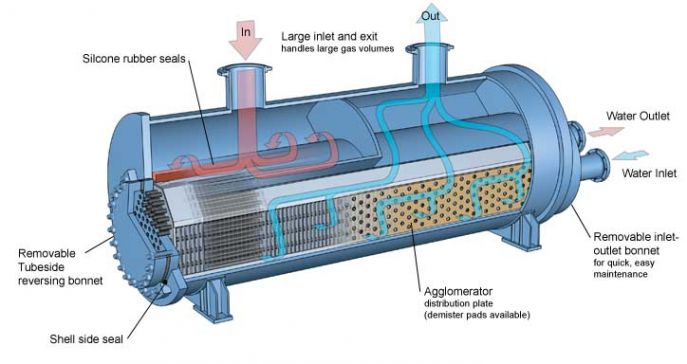

Basco® Type ES Extended Surface Shell and Tube Fin Heat Exchangers

Our Type ES extended surface shell and tube fin heat exchanger is the industry leader for intercooler and aftercooler performance. Its unique patented compact plate fin design provides superior cooling of large air volumes at low pressure drops which means less energy consumption.

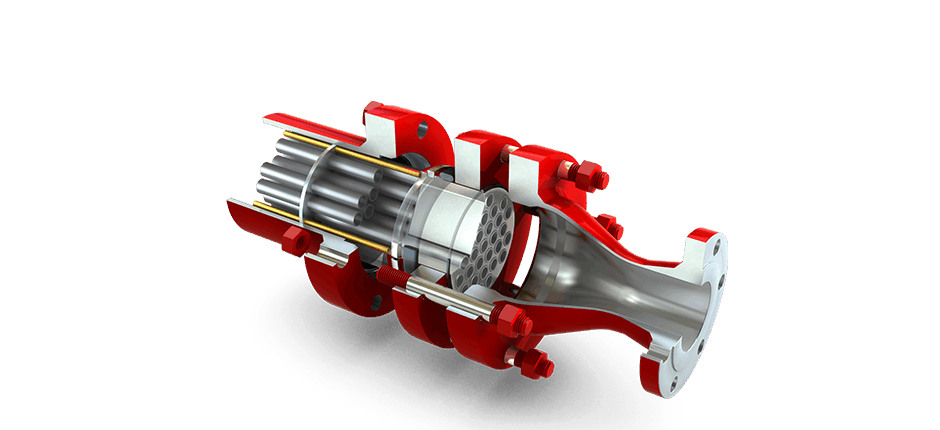

Basco® Type 500 Shell & Tube Heat Exchangers

Our Basco® Type 500 remains the industry standard in ultimate value and long-term reliability. This proven fixed tubesheet shell and tube heat exchanger offers the cost effectiveness that comes with having a highly standardized design, while easily providing various options to meet specific customer requirements.

Our Basco® Type 500 heat exchangers are manufactured in our ISO 9001 certified Buffalo, NY facility and our Suzhou, China facility. We employ Demand Flow Technology (DFT) manufacturing processes where finished goods are made “on-demand” from components and in-line support machining centers. We’ve invested heavily in DFT and embrace the superior quality, improved workflow, and cost controls inherent in DFT manufacturing.

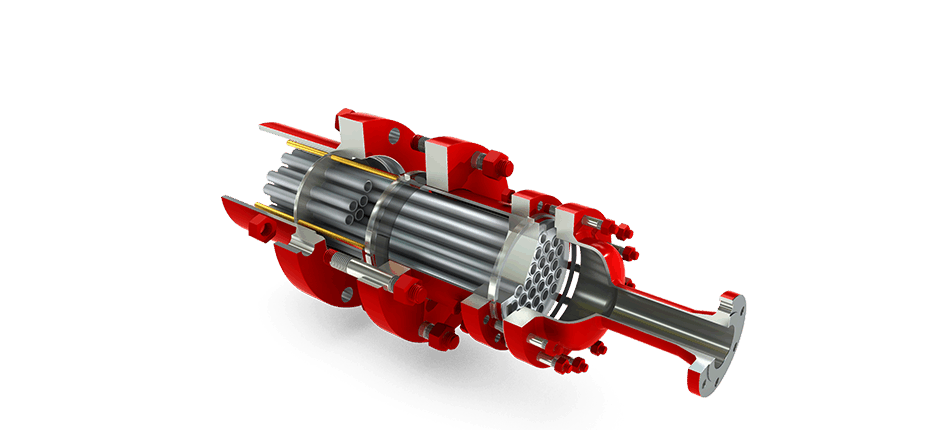

Basco® Hairpin Heat Exchangers

A hairpin design is often more thermally efficient than a traditional shell and tube, which results in a lower up-front cost and lower overall weight. Our experienced designers and engineers can meet any custom cooling requirement.

Removable Bundle Types.

Separated Closure Double Pipe: Type SCDP

- Employs the industry’s most widely used separated head features

- Shell side and tube side closures are separately bolted through, ideal for applications involving wide temperature or pressure differences between the shell and tube side fluids

- In cyclic service, separately gasketed closures are more leak resistant compared to shell and tube designs

- Separate shell and tube side seal configuration. This makes the tube bundle easy to remove, clean and replace.

- Well suited for large imbalance of flow on shellside

- Long fins are used to achieve high thermal performance with minimal pressure drop

Common Closure Hairpin: Type CC

- Single bolted closure design. Ideal for applications involving low design temperature or pressure differences between the shell and tube side fluids

- Enjoys the maintenance advantages of a Separated Closure Hairpin (Type SC)

- The center ring keeps the shell gasket seated during the removal of the tube head for inspection or service

Non-Removable Bundle Types.

All-Welded Hairpin: Type AW

- More cost effective design when removable bundle is not required

- Fixed tubesheet design

Jacketed Pipe: Type JP

- Most economical solution for any heat transfer application

- Fixed tubesheet design

Basco® Custom Engineered Shell & Tube Heat Exchangers

Before there were standard products, there were engineered products, with each heat exchanger designed for the application. Our Basco® shell and tube heat exchangers have filled virtually every heat transfer need for over seventy years. Our experienced design and engineering staff stand ready to bring the best team with the best tools in the industry to bear on your heat transfer challenge. Please contact us to discuss your application.

Codes.

- EU Pressure Equipment Directive (PED) (97/23/EC)

- Chinese Safety Quality License for Boiler and Pressure Vessel

- Australian AS1210

- Singapore Code

- DOSH Malaysian Code

- Canadian CRN, all provinces

- Indian Boiler Regulations (IBR)

- Polish Code

- API 614, 660, 618