Frac Pumper Cube Cooling Module

API Heat Transfer now offers a line of frac pumper cooling modules in a cube configuration for applications that require a lighter, more compact cooling package than our standard horizontal units.

These modules are made with aluminum heat exchanger technology and feature critical design enhancements that greatly improve maintenance, including a large cab-side access door for on-site cleaning.

Turnkey Cooling Solutions.

- 20% lighter in weight than traditional horizontal units

- All-aluminum cooling modules

- Laser-cut, high-strength steel framework

- Custom designed cab-side door for easy access maintenance

- Plumbing of ancillary coolers to internal bulkhead

- Available in both three-point and four-point mounting options

- Complete standard black powder coat of all steel, with custom colors available

- Improved design for ease of cleaning the heat exchanger cores from the outside or inside

Air Cooled Systems

API Heat Transfer is your global source for air cooled solutions. We’re equipped to offer unparalleled air cooled performance to meet the rigorous requirements of mobile and industrial customers worldwide.

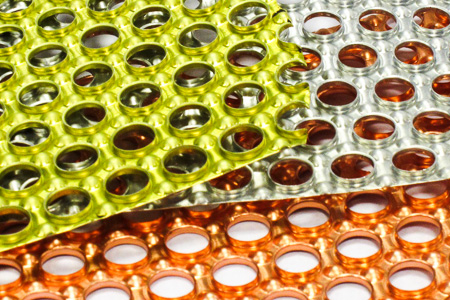

We offer an array of internal and external fin configurations that produce some of the most efficient air-cooled heat exchange cores in the industry, so your engine has more power to perform, even under the harshest conditions.

We focus our engineering expertise on the markets you serve. By understanding your customer applications, we’re able to offer a broad spectrum of components and complete engine cooling systems designed to fit the needs of engine markets across the world.

Our technologies.

API Heat Transfer offers the broadest, most complete air-cooled product lines available.

- CAB or vacuum-brazed aluminum

- Bar-plate

- Micro-channel

- Tube and header

- TBAR

- Copper-brass

- Mechanical-bond

- Soldered

- Bolted tank

TTP Engine Cooling Modules

API Heat Transfer offers Thermal Transfer Products manufactured custom OE engine cooling modules for small gasoline engines to large-horsepower turbo diesel applications. Your choice of a variety of materials and core types (S-BAR, T-BAR, or P-BAR) offers design flexibility for high-performing radiators, CAC’s, or oil cooling. Full system modeling and validation of cooling modules is provided.

Core types

Extruded Tubular Bar | Rugged & Refined

T-BAR™ (tubular micro-channel extrusion) brings you the most refined cooling technology on the market today.

- Engineered with minimal components in an ideally simplified configuration

- Unrivaled strength and rigidity to ensure durable performance

- A flexible design using an extruded flow path

- A high-performing, cost-effective domestic aluminum solution

Plate & Bar | High Volume & Low Variety Applications

P-BAR™ (custom plate & bar) is your best heat-transfer solution for higher volume (qty.) applications, and when competitive costs are key.

- Custom-engineered engine cooling with remarkable heat rejection

- High performance for mobile or industrial applications

- A flexible design

- A cost-effective LCC aluminum solution

Seam Welded Tube | Rugged & Refined

S-BAR™ is the most affordable, high-flow cooling technology on the market today.

- A high-strength automotive style core design

- Durable, multi-row tube to header plate design

- Engineered for use in applications with higher temperatures and heat loads

- A lightweight, reliable and cost-effective aluminum solution

For application help and quoting, visit our full TTP site or contact ttpsales@apiheattransfer.com

Schmidt® SIGMABRAZE Plate Heat Exchangers

Our SIGMABRAZE brazed plate heat exchangers represent the most compact, rugged and cost-effective means of transferring heat in many industrial, process, and refrigerant applications. Built from 316 stainless steel with copper brazing materials, they provide exceptional corrosion resistance. Due to the smaller size and reduced material content, they can be the most economical heat transfer choice.

Remote Cooling Kits

Due to the constraints of space and because of thermal considerations in many environments, an increasing number of commercial power generation installations require the cooling equipment to be remotely located from the generator room.

The kits can be cooled by a separate secondary water source, such as a cooling tower or remote radiator, and can be offered to withstand the secondary water source up to 160 meters above the engine. This makes them ideal for cooling engines situated in the basement of tall buildings, where the radiators need to be on the roof.

Base-frame mounted remote cooling kits consist of:

- Water-cooled charge air coolers

- Jacket water heat exchangers

- CCW and JW header tanks

- All pipework to the engine (jacket water optional)

- A fuel cooler can also be added, if required

- Coolant circulation pump for remote radiator loop can also be provided

Turnkey Genset Radiators

Our line of Covrad Turnkey radiator cooling packages feature our unique high-performance cores and low horsepower fan engineered into a compact envelope. Choose from pre-engineered models or request a custom sized solution based on your specific rating and site conditions.

RhinoDrive™ Turnkey Engine-Driven Radiator

Specify a RhinoDrive™ turnkey engine-driven radiator from API Heat Transfer for your next high horsepower (3MW+ direct drive off engine) genset installation to avoid using costly remote radiators with electric motor driven fans.

- Reduce fan-drive stresses

- Reduce the complexity of your genset installation

- Engineered “Rhino tough”

- Avoid using remote radiators

- Provide a turnkey genset, including radiator, to your customer

- Lower “total cost of ownership”

Copper-Brass Radiators

Our durable and versatile line of copper-brass heat exchanger technology can be applied to any set of operating conditions and is available in a wide range of sizes and types.

BOLTED PLATE-FIN RADIATORS

With thousands of our Bolted Plate-Fin radiators in the field, you won’t find anyone with a better track record of reliability and customer loyalty.

- Pre-engineered or custom engineered to your exact specifications

- Wide product range

- Sizes from 3 sq. ft. to 120 sq. ft.

- Dimpled tubes provide superior performance

- High-efficiency louvered or clog resistant non-louvered fins

- Variety of heavy duty core types designed for any environment

- LF-20 lead free construction for long, worry-free service

- Hemmed Fins provides durability and maximum up-time

BOLTED SERPENTINE RADIATORS

When you need a high performance, cost competitive core with a durable bolted-tank design, our Bolted Serpentine-Fin radiators hit the mark.

We introduced our Bolted Serpentine cores as a cost competitive alternative to our traditional bolted plate-fin cores. Like our plate-fin line, our serpentine cores are built tough and provide enhanced heat transfer performance.

- Low cost of ownership

- Pre-engineered or custom engineered to your exact specifications

- Wide product range

- Dimpled tubes provide superior performance

- High-efficiency louvered cores suited for stationary gensets

- Variety of core types to fit your application

- LF-20 lead-free construction for long, worry-free service

MECHANICALLY BONDED PLATE-FIN RADIATORS

By forming a permanent mechanical bond joint between the tubes and steel header, we’ve created the ultimate in copper-core technology.

- Tubes are robotically expanded and rolled into a steel tube sheet

- Thermal expansion design reduces tube stress

- Rolled tube to header joint provides a long life mechanical bond

- Ideal for high shock and vibration applications

- Ideal for sub-zero temperature site conditions and consequential thermal shock

- High performance dimpled fins provide maximum performance

- The “Gold-Standard” for rail locomotive applications

Options and accessories

We source all ancillary components and combine them into a single, 100% compatible package, saving you time and effort in design, procurement, and installation of these components.

- Optional galvanized steel and heat exchanger coatings provide enhanced corrosion resistance

- Safe and durable fan, belt, and radiator core guards

- Fan shrouds

- Integrated fans and fan-drive components

- Electric and hydraulic motors

- Anti-recirculation baffles

- Hoses

- Coolant recovery tanks

- Level sensors and switch gages

Water Cooled Charge Air Coolers

Custom designed in round shell and tube, or square engine and remote mounted fin designs, our high performance water cooled charge air coolers utilize extended surface cooling fins in either aluminium, copper, or stainless steel to ensure greater thermal effectiveness and durability. This means our customers receive superior performance at a practical price. For over 100 years, our heat exchangers have been trusted among equipment manufacturers in the transportation, power generation, construction, military and process industries.

Basco® Type 500 Shell & Tube Heat Exchangers

Our Basco® Type 500 remains the industry standard in ultimate value and long-term reliability. This proven fixed tubesheet shell and tube heat exchanger offers the cost effectiveness that comes with having a highly standardized design, while easily providing various options to meet specific customer requirements.

Our Basco® Type 500 heat exchangers are manufactured in our ISO 9001 certified Buffalo, NY facility and our Suzhou, China facility. We employ Demand Flow Technology (DFT) manufacturing processes where finished goods are made “on-demand” from components and in-line support machining centers. We’ve invested heavily in DFT and embrace the superior quality, improved workflow, and cost controls inherent in DFT manufacturing.

Custom Oil Coolers

Oil cooling requirements vary widely depending on the type of equipment and duty cycle required. We’ve specially selected fin and tube options to provide the exact performance and durability the application calls for. Whether its high viscosity start up or full temperature operation, our brazed aluminum oil coolers keep it cool. We carefully select each oil cooler to be compatible with your system and each product is carefully designed to provide you the best combination of heat transfer and pressure drop.

Oil Cooler Technologies

BAR & PLATE OIL COOLERS

We’ve identified the best selection of hot and cold fin combinations to provide the ultimate in flexibility and provide the best heat transfer performance in the market.

- Highly flexible design options

- Enhanced internal fin geometries for superior cooling

- Wide variety of hot fins to balance internal pressure drop

- High-efficiency louvered fins for superior heat rejection

- Wide variety of debris resistant non-louvered fins

- Specially designed extruded tanks withstand high pressures

- Ideal for low viscosity fluids

- Welded tanks for a long leak-free life

- Integral bypass relief valves

TBAR OIL COOLERS

Our patented TBAR replaces hot fins and bars with a single extruded tube for increased product durability.

- Highly flexible design

- Patented tube-to-bar joint ensures consistent brazing

- Extruded tubes provide unrivaled durability & fewer leak paths

- High-efficiency louvered fins for enhanced heat rejection

- Debris resistant non-louvered fins

- Specially designed extruded tanks withstand high pressures

- Welded tank to core for a long leak-free service life

- Zinc-Infused aluminum cores for unrivaled corrosion protection

- Low oil side pressure drop

- Stands up to heavy pressure-cycle loads & pressure spikes

- Ideal for high viscosity fluids

- Integral bypass relief valves

MICRO-CHANNEL

- Robust and flexible design

- Louvered and non-louvered air-side fins are available

- Efficient surface to maximize heat rejection

IN-TANK COOLERS

- Compact designs fit inside radiator bottom tanks for transmission oil cooling

- Available in stainless steel and aluminum construction