Evaporation Systems

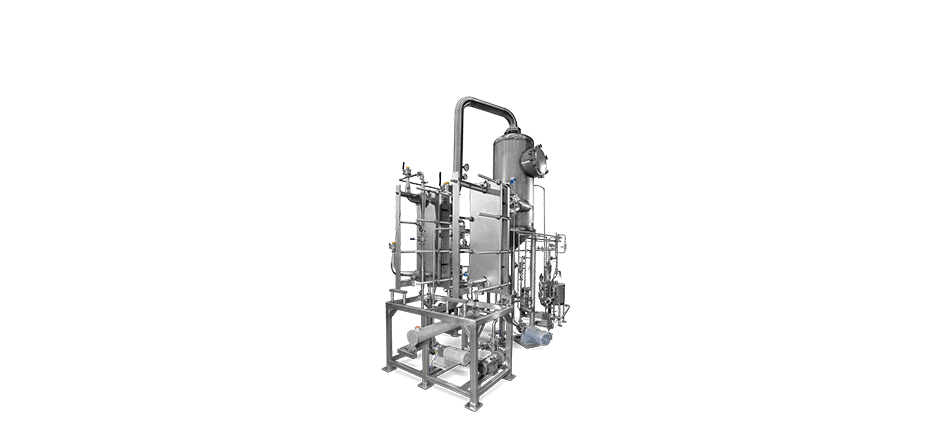

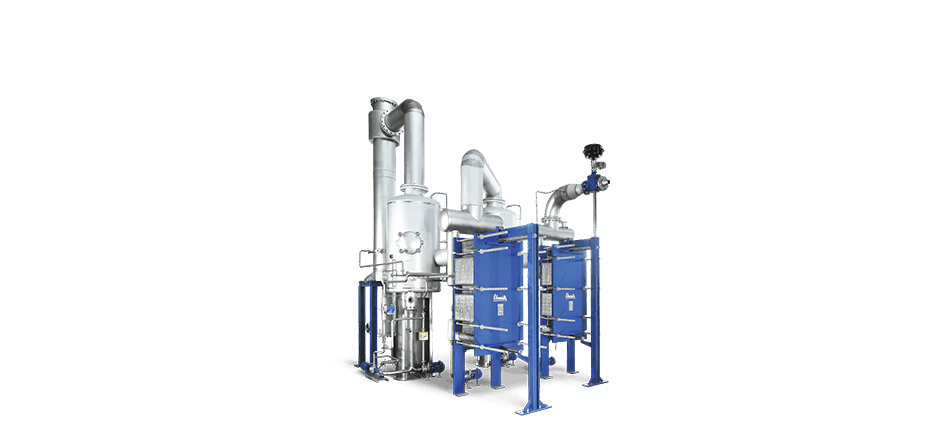

Schmidt® SIGMASTAR Evaporation Systems

Our Schmidt evaporization systems with SIGMASTAR® Climbing-film Plate Evaporators are used in the food industry, in the organic and chemical industry, and for wastewater treatment.

Advantages of the rising-film SIGMASTAR® include

- Superior product distribution due to the thermo-siphon principle

- Extremely short residence time, to guarantee a gentle treatment of the product

- Low pressure losses across the tubes, a benefit of the short tube length

- High concentrations and viscosities are possible due to the high vapor velocity in a rising film

- Clearly defined product flow path. There is no chance of local over-concentration

- Lower cost heat transfer area, compared to other evaporation systems

- No components are welded to the plate surface that can cause corrosion and build up of fibrous materials

- Flexible design – capacity changes can be made easily by adding or removing plates

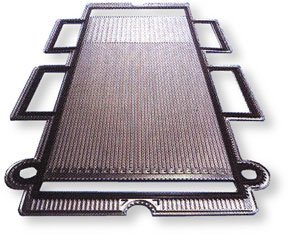

The unique construction of the SIGMASTAR® evaporization plates makes it possible to apply SIGMASTAR® in a number of different evaporization processes. With problem products (e.g. viscous streams, slurries, and liquids with fouling tendencies) which cannot be processed with falling film evaporators, the SIGMASTAR® evaporizer performs especially smoothly and successfully.

Each of these pressed plates is approximately 0.9 m wide, 1.8 m high with longitudinal, sinus form corrugations, which extend over the full width of the plate. The flow passages on the plates are sealed by gaskets held in place by adhesive. This construction has several technical advantages.

Process Description

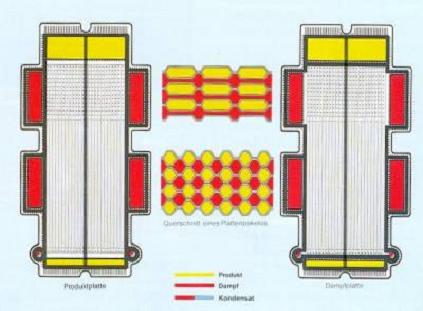

Our evaporation systems are constructed of steam and product plates, where steam condenses on one side of the plate while product boils on the other. Plates are aligned in the system so that vertical channels form in a circular shape. These channels can be conisdered “psuedo” tubes, resulting in a construction that combines the advantages of both plates and tubes.

Due to the special design of the upper part of the heat transfer surface, the heating steam is distributed evenly over the complete width of the plate. The cross-sectional flow area is the same on both sides of the plate, which ensures a well balanced feed into the heating channels.

Two Product Processing

Also available is our SIGMASTAR®-45V plate, a variation of the SIGMASTAR®-90V. This plate has an additional gasket down the center of the plate, which allows two products to be processed simultaneously. In this set up, steam can enter either the left, the right, or both sides of the plate, and the condensate exits from the bottom of the corresponding side of the plate. This can be seen in the figure below:

The SIGMASTAR®-90V and the SIGMASTAR®-45V can be combined in many different ways to increase the flexibility of our systems, especially for small duties. As the dimensions of both plates are identical, the same frame supports can be used. Expansions and modifications involving both plate types are possible at any time.

Applications

- Food and Beverage

- Beverage

- Brewing

- Food ingredients

- Sugars and starches

- Process Industries

- Chemical

- Pharmaceuticals, nutraceuticals, and cosmetics

- Wastewater treatment